What is Operational Excellence?

In the business world, the term “operational excellence” is becoming extremely popular. But what is “Operational Excellence”? We need to put Operational Excellence into context before we can define it. “Operational Excellence” refers to efforts made at the individual process level within a company. In reality, it necessitates using Deming’s Circle: design, execute, and improve any process.

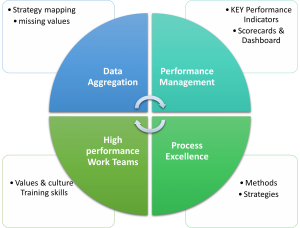

Simply said, operational excellence means producing or providing goods and services to the highest possible standard. To begin, we can put it into action by optimizing at each level. It all starts with people, then processes, and finally resources or assets.

Operational excellence transforms a company that effectively conducts and executes value-driven activities safely and efficiently. Furthermore, digital transformation can assist businesses in achieving operational excellence and transitioning from automated to autonomous operations.

What is the current state of operational excellence in the process industries?

Numerous process sectors have so far tried to achieve operational excellence using a variety of ideas and techniques, but they have encountered various challenges with standardization, adoption, and scalability that have hindered their capacity to enhance and boost output quality.

The complexity of the process, its opaque operation, and the overall organizational culture’s resistance to change were the primary challenges.

Why to choose Digital Transformation?

The major role of digitalization is to assist in the reduction of the complexity of manually operated processes and the creation of a transparent overview of the process by utilizing the vast data available.

The following are some solutions that digital transformations bring specifically to process industries: data reporting solutions like dashboard development or asset health monitoring, overall equipment efficiency.

Data-driven solution models such as soft sensors, or advanced solutions such as predictive maintenance rather than heuristics/experience-based approach, which reduces reliance on trained/experienced people and shortens the training period for novice operators.

Operational excellence using Digitalization in the process industry

It entails using well-known and stable concepts of operational excellence in conjunction with digital solutions to improve the performance of people, processes, and assets; in other words, it will assist an industry in upskilling entire organizational culture. By narrowing the gap between departments and levels within the organization’s hierarchy.

Optimized Organizational Culture

Many industries have begun their digital transformation journeys, and those who have not yet begun their journeys plan to do so at various levels of digital transformation. According to a Fujitsu survey, 44 percent of respondents from offline firms believe that by 2025, more than half of their non-automated business operations will be automated.

Industries should be able to connect the stages of digital transformation; they need to know where they are in the process and what output they want, since alternative solutions can be supplied based on the requirements using a step-by-step method.

From the initial sensor installation to the conversion of manual data to digital data, the data is then centralized in DCS for control and monitoring. A reliable communication layer between the IT and OT networks, as well as an analytic solution for monitoring/modelling process data.

The Operating Training Stimulator (OTS) can also be developed to give new operators plant experience, bridging the gap between a trained and untrained operator. Data visualization and reporting ensure that the process is understood and clarified. Data can be utilized to build a first principal model and check the data’s theoretical and actual trends. For non-linear processes, data-driven models such as regression models can be created. Soft sensors for parameters with a given time lag are developed so that live empirical values are accessible before time, condition-based monitoring to ensure a batch follows a golden batch profile and we get the best yield.

Conclusion:

Upskilling of people, processes, and assets is a necessity for process industry, operational excellence and its principle’s assist in performing well in the process industry at all levels of the business. But hindrance due to complexity of the nature of operation in process industries became a major problem. Digital transformation reduced it by providing highest level of transparency in the manual operational process and upskilled individuals in the organizational hierarch.

Written by,

Adarsh Sambare and Kishan Nishad

Data Scientists

Tridiagonal Solutions