“Digital Transformation” is the adoption of the novel “Advanced Digital Technologies” to create modified processes from existing traditional processes. With Digital Transformation for the Process Industry being implemented in the Chemical/Manufacturing space, we have gained the realization that these tech stacks have high potential to achieve and improve efficiency, value.

Digital Transformation is a part of “INDUSTRY 4.0”, which involves wider concepts such as solutions on deep analytics, shop floor data sensor, smart warehouses, simulated changes, plus tracking assets and products. Industry 4.0 is an overall transformation taking place in the way goods are produced and delivered.

Process Industry is under constant pressure to meet the production target while minimizing the cost and maximizing product quality. Digital Transformation of the underlying assets can help them achieve this target. However, only incremental innovation and digital transformation have been seen in the last decade.

The major fundamental challenges in manufacturing process digitalization, are listed below:

- Outdated Systems

- Resistance to change (Disruptive V/S Incremental Change)

- Rigid Infrastructure

- Privacy Concerns

- Lack of Overall Digitization Strategy

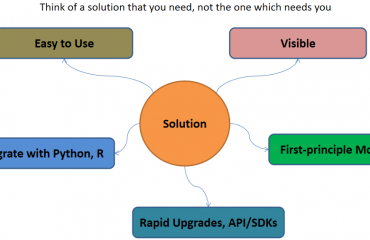

In this article, an approach/ framework for digital transformation for the process industry will be discussed keeping the fundamental challenges in focus. A flexible framework that needs to change as per the industry requirements.

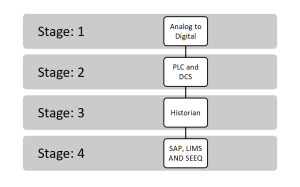

4 – Staged approach for an effective Digital Transformation in Manufacturing Space

Following are the stages for the journey of digital transformation:

- Stage: 1 Data Availability

- Stage: 2 Data & Asset Management

- Stage: 3 Data storage

- Stage: 4 Operationalizing the data

- Stage: 1 Data Availability

Utilization of manual operation or having limited or no digital control. But the manufacturer is ready to modernize its system from analog to digital. Focus being on adapting the right solution, sources of data, the adaption of the sensor, convert manual data to digital. One key aspect at this stage is to implement and integrate these sensors/IOTs, which follow the open protocols for communicating with the 3rd party applications.

- Stage: 2 Data & Asset Management

After the application of the sensor and converting manual data to digital, the data is then centralized to the PLC and DCS, to permit control, monitoring, and reportage of individual elements and processes at one location. This stage also becomes critical as basic instrumentation and controls would be the foundation for enterprise-wide digital solutions. It also makes us to think about the Integrity of the data – accuracy, consistency, completeness. Representation of data becomes very critical as we expect it to be speaking for the process itself, additionally maybe also about how the operations were considered on the shop floor.

- Stage: 3 Data Storage

Although DCS/SCADA enables the shop-floor team to take the decisions, but it is limited in terms of storing the historical data, which becomes a key for Digital transformation. To our rescue, comes the historian, which extends its capability to store large volume of data, additionally, today everyone is also talking about cloud-ready solutions, which provide us unlimited/remote storage/compute capability to process and derive the insights from our data.

- Stage: 4 Operationalizing the Data

Having your data available in the OT network still doesn’t help in operationalizing the data. Today, every Industry in targeting for remote monitoring, online notifications, and more. To achieve such targets, one really needs a robust layer of communication between the IT/OT network and moreover, an analytic solution for monitoring/modeling the process data. The COE team sitting remotely can monitor the real-time operations, support the operations with technological know-how.

Conclusion:

It is very much evident that Digital Transformation is of high-value journey for the Manufacturing / Process industry, but it really depends on the approach and the methodology which was undertaken to achieve the KPIs. Moreover, it also depends on the people who are involved in this journey of transformation. One needs to be well acquainted with technology, process challenges, the scope of improvements, and others.

Tridiagonal Solutions – a company specializing in providing knowledge/ insights-based solutions for the Process Industry. With strong process domain knowledge, we help companies in KPI-based advanced Analytics

Written by,

Adarsh Sambare

Data Scientist

Tridiagonal Solutions

https://dataanalytics.tridiagonal.com/