Good morning, good afternoon or evening to all. Pick the one which belongs to you!

So, before we get to the centerpiece of the article, just want to set some context. The focus of this article is not too technical, nor too generic, but this article is dedicated to all among us who in some way or the other is related to the field of digitalization in the manufacturing industry.

Sometimes we are too much taken by the technicality of the problems, that we stop thinking about it in a crude engineering way. Don’t you feel so?

Sometimes, it’s suitable (and a need too!!) – to rethink the objective and solve it by taking a logical approach, indeed a practical one.

Have you ever felt that, with the advent of the technology (ML and AI I mean!) we try to force-fit the models everywhere without any proper definition and evaluation of the requirements, needs or investments (ROI, in other words). But still not clear, right?

A fun fact, though I do not hold any statistics on this one, I still feel that – “The rate of an engineer transforming to a data scientist is higher than that of literacy rate itself.” Do you agree?

But, are we really making any practical use of this transformation? It’s an observation, that before we apply any model to the process data, we force ourselves to think like one, right? So we miss out on the logical apprehension or the practical mindset that goes behind it.

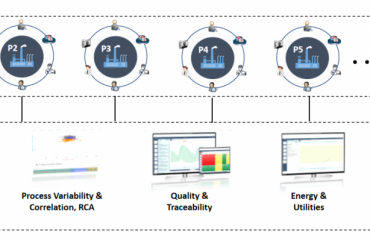

Hail Model! That’s right. Machine learning and AI have definitely empowered us to solve many engineering problems in any easy and comprehensive fashion, such as – Real-time predictions of the quality parameters, forecasting the next probable failure event for any asset(s), and many more. It has democratized the Industry in many ways, by detaching the long going dependency on the lab analysis in many operations, dependency on simulations to get the inflicting values of the quality parameters and many more. It has drastically reduced the time for getting the results much earlier, almost in real-time, which earlier took days to get generated from other siloed mechanisms.

But do you really think that these can solve all of your problems? No, right? Moreover, sometimes the infrastructure and technology cost behind such an application is huge, even more than ROI itself. So what should we do? Should we stop thinking about these applications? Or, should we wait till this cost plummets. The answer is a “No”. Then what should we do?

There needs to be a logical approach behind these, which means that someone has given us the power to use the technology, but how to use it, is up to us. In this case, the driver of the technology or the digitalization leaders have taken ownership of such programs. He/She should be well versed with the technology targeting the manufacturing industries. Plethora of solutions are available, so which one to select? This is the next big question, which connects our previous one. So the answer is that the solution should be such easy to use that even the operators or the engineers can learn it. Right? I mean what’s the use of such technology that doesn’t make your life easier. Correct!!

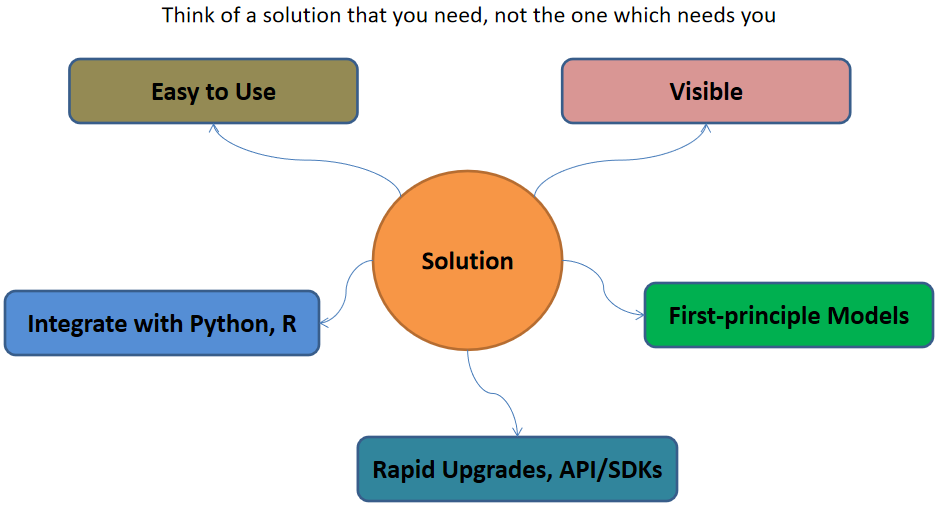

So, coming directly to the solution part, the evaluation criteria or the metrics to keep in mind, before investing, but after envisaging the requirements and need:

- Comprehensible: Simple, easy-to-use solutions – that can get into the hands of operators and engineers (The real industry drivers!!)

- Blend-able: Capability-wise – Easy to mingle with the open-source and widely accepted programming solutions, such as python, R and MATLAB

- Reform-able: Solution should be capable enough of upgrading itself with the uplifting of the technology. Or else, it will get outdated soon. This becomes a really important criteria as one always invests in keeping long-term goals in mind, and not the short ones.

- Visible: The solution should be capable of providing Visuals – be it in terms of trends in real-time or 3D CAD models, like the one in digital twin, which we all dream about.

- Though we say models are a black-box, we still want to see what it is doing, right? At least, what is it outputting? Operators don’t care about which model you apply or what technique you use, then just want to see what is happening inside that piece of equipment with a better view, that’s it.

- Solvable: We all are engineer’s correct? We want to solve equations and correlations, it’s our job. So the solution should be capable enough to allow you to solve some complex algebraic equations – we call it first principle models.

In case you are starting your digitalization journey or being stuck somewhere, we (Process Analytics Group) at Tridiagonal solutions can support you in many ways.

We run the following programs to help the industry along with various needs:

- We run the POV/POC program– For justifying the right analytical approach and evaluating the use cases that can directly benefit your ROI.

- A training session for upskilling the process engineer – How to apply analytics at its best without getting into the maths behind it (How to apply the right analytics to solve the process/operational challenges)

- Python-based solution– Low code, templates for RCA, Soft-sensors, fingerprinting the KPIs, and many others.

- We provide a team that can be a part of your COE– That can continuously help you to improve your process efficiency and monitor your operations on regular basis.

- A core data-science team (Chemical Engg.) that can handle the complex unit processes/operations by providing you the best analytical solution for your processes.

Written by,

ParthPrasoon Sinha

Sr. Data Scientist

Tridiagonal Solutions