How to Achieve Operational Excellence through Visual Analytics (ML Model Deployment. Visual Analytics. ROA)

- Save to Calendar

- 24/02/2022 - 10:00 am - 11:00 am EST

Learn How to Extract Value out of Process Data, Deploy Machine Learning Models, and Achieve Operational Excellence through advanced visualization of your Process Data.

Today, everyone is trying to extract value out of plant/process data and evaluating data science/analytics solutions for their manufacturing plants/ production fields. However, everyone is at different (analytics) maturity level and not very clear on a roadmap, and what should be the key elements of a solution that will actually realize the ROI. ‘Data Science’, ‘Machine Learning’, ‘Digital Twin’, are good data-driven techniques, and technology has evolved over a period of time, that has enabled the implementation of such solutions. It could be in terms of data connectivity, new algorithms, availability of ML packages/libraries, automl, development tools, etc. However, its application in the Process (Manufacturing) data needs to be understood appropriately.

DATA ANALYTICS FOR OPERATORS AND NOT (ONLY) DATA SCIENTIST

We are all surrounded by plethora of data science and so-called analytics solutions. Most of the solutions are designed keeping ‘Data Scientists’ in mind – to build ML models, run the models and tune the models. However, when it comes to Manufacturing data, we are dealing with ‘Time-Series Live Data’, the frequency of data is in secs/minutes, and there are so many factors involved that should be considered. The value of data-driven techniques is actually realized, when the ground-level person like an operator, process engineer, maintenance engineer on the field is able to consume it and make some insightful decisions. This is a team who monitors the current state of the system/ assets / operations through DCS/ SCADA systems. The ML models should enhance these capabilities of ‘MONITORING’.

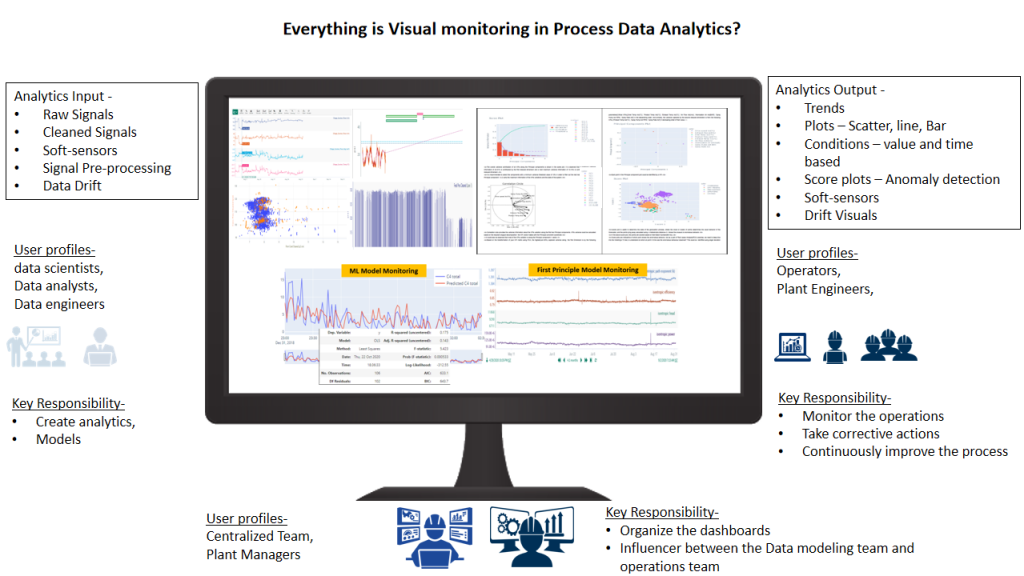

EVERYTHING IS MONITORING (VISUAL ANALYTICS)

As the Operators/Process/Production Engineers are dealing with live/streaming data and monitoring the plants, data analytics should enhance these monitoring capabilities. These solutions should have such visualization capabilities, which can enable quick insights and decision-making process. The ML models built should be deployed in the form of ‘Visual Analytics’, so that the actual consumers can use it in a meaningful way.

Few examples of Visual Analytics:

- Scatter Plots, Tree Map,

- Correlation Circle – to identify highly correlated parameters

- Statistical Process Control limits monitoring

- Advanced Process Control set points monitoring

- Process Finger Print/Golden Batch monitoring

- Composite Conditions Monitoring

- ML Model -Advanced Visualization (Hoteling T2 Plots)

Who should attend:

- Digitalization Team

- Technology leaders

- Data Science leaders

- Data Analysts

- Production / Operations Head

- Smart Manufacturing

- Maintenance Heads

- Plant heads